Second, the bottom copper is a ground plane, and nothing else. Routing both sides of a PCB leads to a whole other series of issues. If you want a connection between the top and bottom of the board, you need to solder the connection on the top and the bottom, and you also need to flip the board and do some milling on the bottom. This is a two sided copper board, but drilled holes will be unplated. Wait, surface mount makes this easier? Yup… Using surface mount components only means I don’t have to drill holes for any component leads, and I only have to solder components on the top side. First, all the components are surface mount, and only on the top side. I used three design tricks to make my life a little easier. Replicating this on a mill at less resolution just won’t cut it.

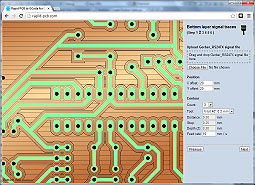

This design is a reasonably aggressive test of the milling process. If you read through my iModela PCB Milling post, you’ll know that the ATMEL megaAVR TQFP package needs PCB milling resolution of 8 mils or smaller.

The camera flash really brought out their highlights. There are a couple of scratches on the copper that look worse than they really are.

0 kommentar(er)

0 kommentar(er)